Positive Displacement Meter

Sectors of application

Oil depots

For oil product reception and loading stations for tank truck, tank car and ships.

Hydrocarbon transportation

Distribution of fuel oil or fuel by road tanker.

Aircraft refuelling

Aircraft dispensers and aircraft fuelling tankers.

Army

Depot supplies and loading of trucks.

Transport companies

Refuelling of locomotives, trucks and public transport coaches.

Marine applications

Refuelling of ships.

Mining sites

Refuelling of trucks or site machinery.

Operating principle

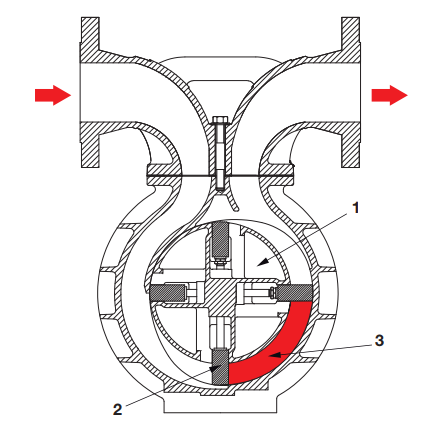

The product enters the measuring chamber following the direction of the arrow. The rotor and blades assembly (1-2) is set in motion by the pressure of the liquid on blades. A certain

amount of liquid (3) is held between 2 blades and then directed to the discharge manifold. The volume of liquid measured at each rotation is therefore equal to 4 times the measured

quantity (3). The smooth curves the meter pieces provide a steady, non-fluctuating flow resulting in low head loss

Key points

Reduced pressure loss

0.3 to 0.5 bar at maximum flow rate.

Low maintenance costs

Simple and robust design with mechanical components

interchangeable between the different models.

Stability of measurements

Accuracy of measurement guaranteed over a period of many years without any drift in the calibration curve.

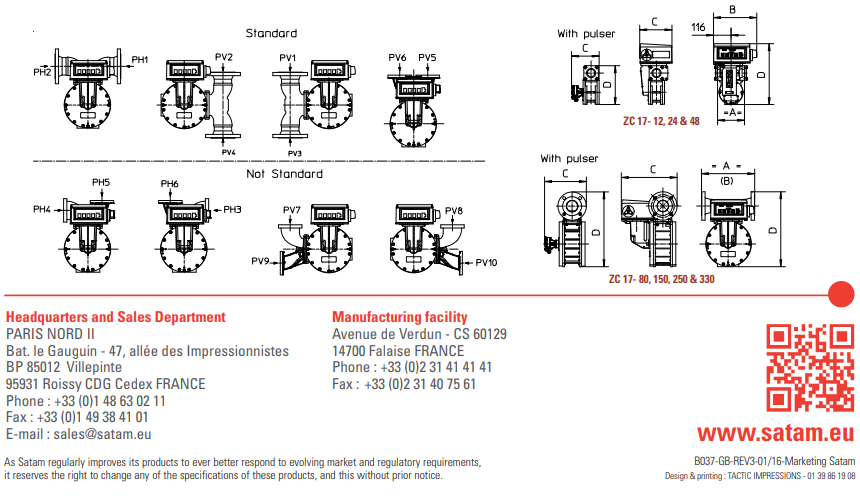

Modular design

Wide range of accessories for performing customized measurement applications.

Robust construction

Flowmeter manifold is separated from measurement chamber to eliminate any possible influence of external mechanical stresses on measurement accuracy. Few moving parts.

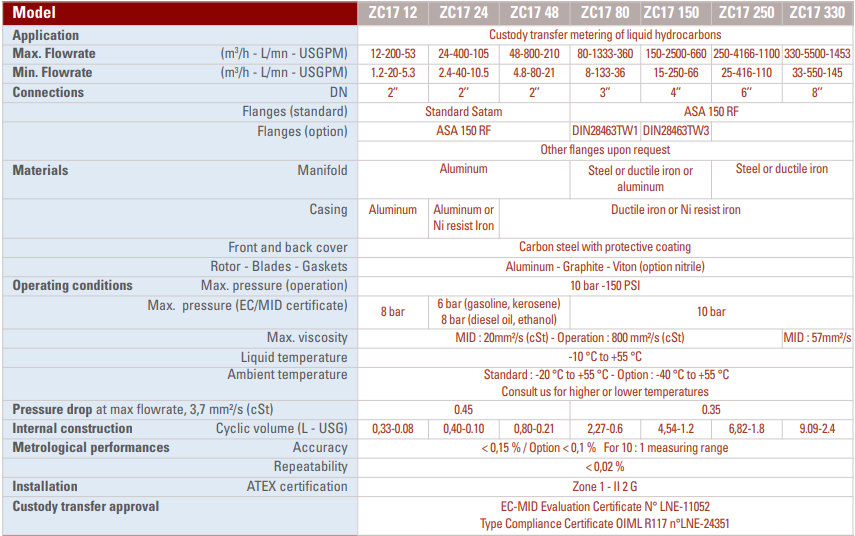

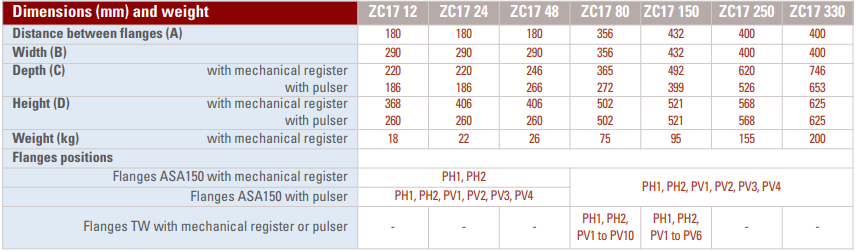

Technical data – PD meter ZC 17